The concrete slump test measures the consistency of fresh concrete before it sets. It is performed to check the workability of freshly made concrete, and therefore the ease with which concrete flows. It can also be used as an indicator of an improperly mixed batch. The test is popular due to the simplicity of apparatus used and simple procedure. The slump test is used to ensure uniformity for different loads of concrete under field conditions.

The slump is carried out as per procedures mentioned in ASTM C143 in the United States, IS: 1199 – 1959 in India and EN 12350-2 in Europe.

Generally concrete slump value is used to find the workability, which indicates water-cement ratio, but there are various factors including properties of materials, mixing methods, dosage, admixtures etc. also affect the concrete slump value.

Equipment Required For slump cone Test

- Mould: Shape of the mould is a frustum of a cone. The cone is known as slump cone. Slump cone is made of steel, plastic, etc. Its height is 12 inches (30 cm). The diameter of the base opening is 8 inches (20 cm) and the top opening is 4 inches (10 cm).

- Base plate: Base plate may be made of Aluminum, polymer, steel, etc. It may be equipped with a holding attachment.

- Tamping rod: Temping rod used in the slump test is made of steel. Tamping Rod is usually 24" long and has a diameter of 5/8" diameter. Temping rod used in the slump test is made of steel. Tamping Rod is usually 24" long and has a diameter of 5/8" diameter

- Tape measure: Standard tap should be used for measurement

Concrete slump Cone Test Procedure

- Clean the internal surface of the mould and apply oil.

- Place the mould on a smooth horizontal non- porous base plate.

- Fill the mould with the prepared concrete mix in 4 approximately equal layers.

- Tamp each layer with 25 strokes of the rounded end of the tamping rod in a uniform manner over the cross section of the mould. For the subsequent layers, the tamping should penetrate into the underlying layer.

- Remove the excess concrete and level the surface with a trowel.

- Clean away the mortar or water leaked out between the mould and the base plate.

- Raise the mould from the concrete immediately and slowly in vertical direction.

- Measure the slump as the difference between the height of the mould and that of height point of the specimen being tested.

Result For Slump Cone Test

Slump for the given sample= _____mm

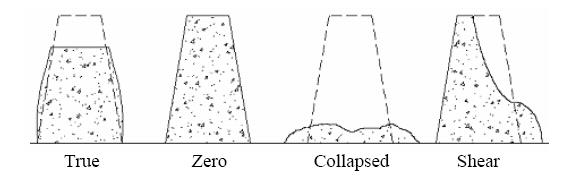

When the slump test is carried out, following are the shape of the concrete slump that can be observed:

Figure-: Types of Concrete Slump Test Results

- True Slump – True slump is the only slump that can be measured in the test. The measurement is taken between the top of the cone and the top of the concrete after the cone has been removed as shown in figure-1.

- Zero Slump – Zero slump is the indication of very low water-cement ratio, which results in dry mixes. These type of concrete is generally used for road construction.

- Collapsed Slump – This is an indication that the water-cement ratio is too high, i.e. concrete mix is too wet or it is a high workability mix, for which a slump test is not appropriate.

- Shear Slump – The shear slump indicates that the result is incomplete, and concrete to be retested.

1 Comments

thank you for this amazing knowledge

ReplyDelete